Technical Information

Hi-Quality Raw Materials

The wood we use is FSC® certified and is imported from Finland and Sweden. FSC® certification (FSC-C074674) ensures that products come from responsibly managed forests that provide environmental, social and economic benefits.

We use profiled solid and profiled Glue-Laminated spruce timber. It is manufactured in our factory, which allows us to retain and control the wood’s quality throughout the entire manufacturing process.

Glue-Laminated timber is both strong and tough

Glue-Laminated timber is a versatile and innovative construction material used widely in the manufacture of residential projects. Laminated logs are made with multiple layers of solid pieces of wood bonded together with high-strength adhesive to form a single structural unit. They offer superior strength and stiffness over traditional timber logs and are 50-70% stronger than regular wood. Laminated logs are not only cost-effective as settle less than standard logs and have no cracks, but also highly customizable to fit special needs or precise dimensions.

Solid timber is used mostly for garden, summer cabins or saunas.

Different wood for different parts

We mainly use northern spruce timber for our constructions. Northern spruce has a slow and steady growth, much slower than most other trees. While growing it is exposed to the extreme conditions which makes the wood durable and robust. It is a perfect lightweight and stable high-quality convenient building material.

Another types of wood are used for our specific products.

Windows and doors are made entirely of laminated pine scantlings. Laminated pine is a stable, safe, and fluctuating temperature – resistant material.

For floor constructions we use impregnated northern spruce timber. This kind of wood is resistant to many environmental effects such as rot, insects, mold, and fungi and therefore lasts much longer.

For saunas we turn to soft wood like aspen, black alder or abachi. This type of wood has low moisture content, is resistant to wrapping and cracking even under extreme conditions. It is lightweight, durable, has a pleasant scent and smooth texture. It does not secret resin, create splitters or get too hot.

Flexible Production Process

Our production is notable for being flexible. It is based on detailed design drawings from our designers. The artisans pay great attention to each and every part of the product. Should it become the necessary, the entire assembly line is adapted to the needs of the client – and this, in turn, enables us to fulfil our clients’ specific requirements.

Paying attention to each and every part during the production process

Our timber is jointed in one of two ways: lengthwise (in order to obtain timber of sufficient length) or width wise (in order to obtain timber of sufficient thickness).

Our production facilities have a fully automated machine that allows for exceptionally precise cuts, which means that the building is tightly joined together.

Outside walls, divisions, floor slabs and the roof are manufactured as separate elements at the factory. This way, we are able to ensure precision and fast assembly at the worksite.

Most of the assembly lines are automated and computerized. This enables us to reach a high level of productivity, ensure our wood products are of a high quality, expand our assortment and implement the specific requirements of our clients.

Focusing On Every Detail

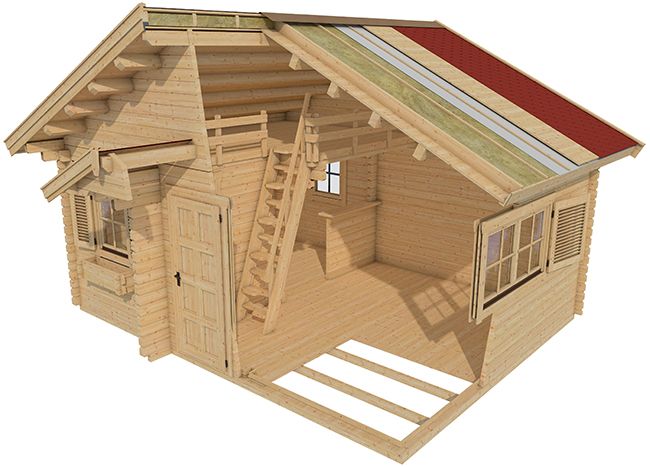

We pay a lot of attention to each and every detail of a building, and we have highlighted several of the more important parts of a house.

Click or mouse over house structure element to view details.